Energy saving at anchor

Yachts spend about 90% of their time at anchor or docked, on average, with generators contributing about half of their total emissions. Research conducted by Heesen into addressing the hotel load has come up with some innovative solutions with significant potential for reducing energy consumption

When optimizing a yacht’s sustainability, the initial thought might be to focus on cleaner main engines with lower emissions. The yacht industry is indeed investing significantly in that direction. However, alternative fuels like methanol and hydrogen, although promising, will take time to become available in sufficient quantities and require major technical modifications to the design of yachts. But this doesn't mean there are no short-term gains to be made in emission reduction.

Press play if you prefer listening to this content.

YETI sustainability index

To gauge the true environmental footprint of superyachts, the industry has collaborated with the Water Revolution Foundation to develop the Yacht Environmental Transparency Index (YETI). This methodology evaluates a yacht's environmental impact across more than 30 different criteria, resulting in a YETI score. By quantifying sustainability, yachts can be compared objectively, and shipyards and clients can consider sustainability in their choices. Heesen is among the first users of the YETI index.

Erik van Mourik

Manager of Cost Accounting Design & Development at Heesen

Only 500 sailing hours per year

YETI members conducted extensive research on average yacht usage using the automatic identification system (AIS), mandated for larger vessels to communicate their positions, to map the sailing behaviour of numerous yachts. Erik van Mourik, a design and development manager at Heesen, highlights the findings: "It turns out, for instance, that a typical yacht is under way for only five to ten per cent of the time. For our yachts, about 500 hours a year is the average. The rest of the time it is either at anchor, accounting for 30 per cent, or in port, making up 60 per cent. While at anchor, all the energy required for the hotel load is provided by the generators. In port, generators supply about 15 per cent, with the remainder from shore power."

Half emission due to hotel load

Although the propulsion of a yacht demands considerably more power than the hotel load, the extended periods of stationary operation contribute significantly to the environmental impact. Van Mourik explains: "We calculated that about half of the yacht’s total emissions can be attributed to the generators and the hotel load. And unlike propulsion, there is immediate and substantial room for improvement in this area."

Substantial consumption by heaters

Heesen has undertaken detailed research during sea trials and maiden voyages to identify potential areas for improvement. “A significant amount of power is consumed by electrical heating, both from the heating elements in the fresh air unit and the electrical boilers," a Heesen engineer explains. "It was notable that the fresh air unit consistently uses about 6 to 7 kWh of power, because the outside air is first cooled to dehumidify it, and then reheated. Also, the boilers operate almost continuously to ensure immediate hot water throughout the yacht. And there is often a swimming pool or jacuzzi on board that needs heating."

Waste heat as viable option

For these applications, using waste heat is a viable option. "A generator operates with an efficiency of about 50 per cent, meaning half of the fuel is converted into heat," says Van Mourik. "Replacing electrical heating elements with waste heat solutions is already feasible with relatively modest investment, and offers substantial energy savings. We calculate that by harnessing waste heat, hotel load energy consumption can be reduced by as much as 10 per cent. However, this would mean installing heat exchangers alongside the electric heaters that are still required if the yacht uses shore power instead of generators.”

Large savings potential

Van Mourik underscores the significant savings potential of waste heat recovery: "There are numerous heaters on a yacht, including those for fresh air, boilers, and swimming pools. All of these could potentially be replaced by waste heat systems. Furthermore, implementing waste heat recovery involves relatively small investments with substantial savings potential. In fact, we already frequently utilise heat exchangers for swimming pool heating, resulting in significant energy savings. Waste heat systems can be retrofitted on existing yachts."

Increased awareness

The YETI index already considers the use of heat exchangers, resulting in a more favourable score for yachts. Erik van Mourik anticipates a growing adoption of waste heat solutions in yachts. “There is an increasing awareness of sustainable technologies. Our customers frequently embrace electric vehicles and implement sustainable measures in their homes, indicating a growing demand for sustainability in the yacht industry as well."

Additional hotel load reducing innovations

Apart from utilizing waste heat, the hotel load study has identified other promising areas where energy consumption at anchor can be reduced.

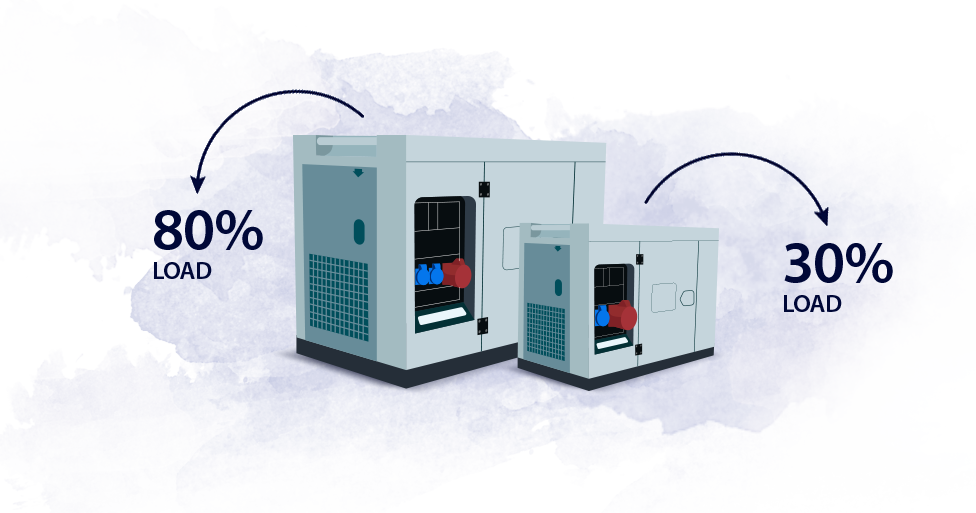

PEAK SHAVING

A generator operating outside of the efficiency zone will cause increased fuel consumption, and higher emissions. With a peak shaving system a smaller generator should be selected which is maintained inside the efficiency zone of approx. 80% load. The system also prevents the second generator to start. The peak shaving system can save up to 3% in fuel consumption (50% load compared to 80% load).

HEAT PUMPS AND DOUBLE-GLAZING

Similar to sustainable homes, integrating a heat pump in conjunction with double-glazing can result in substantial energy savings. Nevertheless, it's worth noting that both of these innovations entail relatively high investments.

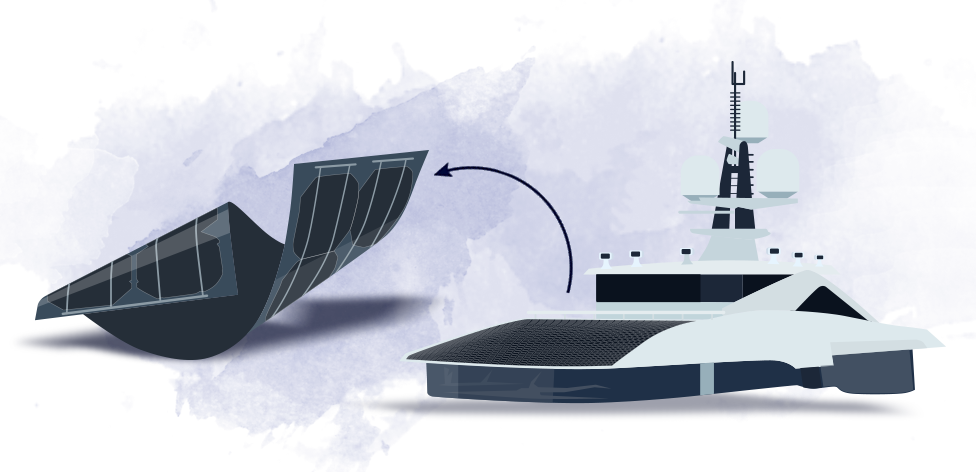

SOLAR POWER

A viable option is to include solar panels on the mast for free sustainable power. A composite mast with integrated thin film solar panels is one of the promising options that Heesen is currently looking at, together with solar cells integrated into fabric for sun awnings.