INCREASING HULL EFFICIENCY

TO REDUCE OUR FOOTPRINT

The route to sustainable yachting is long and challenging. With the launch of BlueNautech Heesen is committed to taking first steps to reduce the industry’s impact on our planet. One of the most effective ways to improve fuel-efficiency is through hull design and Heesen has turned hull efficiency into a science.

First-time visitors to the Heesen shipyard will surely remember the moment they pass through the doors from the reception area into shed 1. In contrast to the rest of the shipyard this is a traditional building shed, not a dry-dock, which means you are in for a close encounter with the impressive bow and hull of the yacht in build. It’s historic ground for Heesen, with over 40 years of history, and continuous evolution in hull design. Senior naval architect Sjoerd van Herk hasn’t been around for that long, but together with his design team he can draw on the collective knowhow and innovations of the many yachts created here.

But there’s one yacht in particular that speaks to the imagination of everyone at Heesen: Octopussy. She was designed to be the world’s fastest superyacht back in 1988. Against all odds she crushed the speed record at 53.17 knots and put the relatively unknown shipyard from Oss on the map.

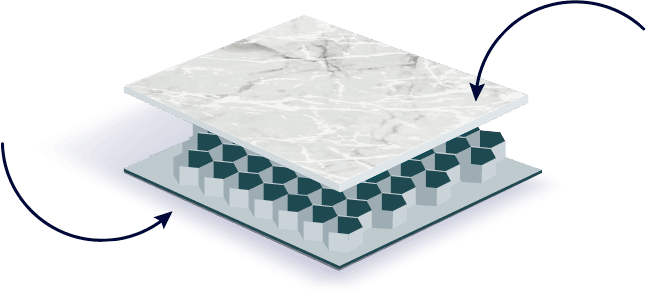

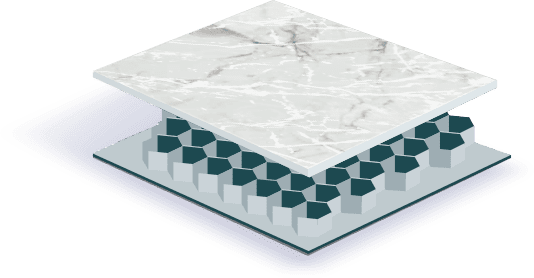

“This incredible performance was not only the result of her striking, speedboat-like hull shape, and potent MTU water jet propulsion,” says van Herk, “but also because of her clever lightweight construction, using experimental honeycomb interior panelling to keep the weight and drag to a minimum. This obsession with weight saving and efficiency is still omnipresent at Heesen.”

Press play if you prefer listening to this content.

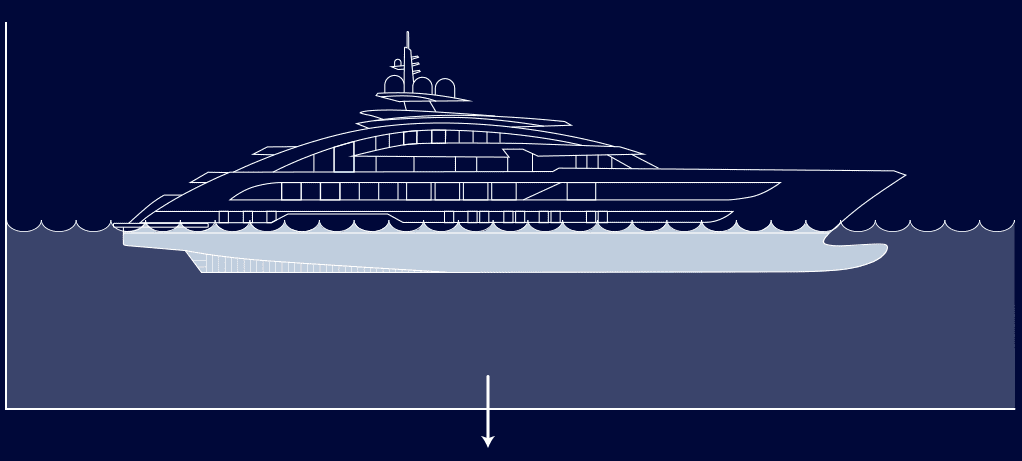

Less weight means less displacement

One of the most effective ways to improve hull efficiency is by reducing the weight of a yacht. Less weight means less displacement and drag.

More weight = More surface = More drag

The science of efficiency

Obsession, or science? Let’s start with a simple definition of hull efficiency:

"Hull efficiency basically means that you want to minimise drag, so you need less engine power to propel the yacht,” explains van Herk. "There are two ways to reduce drag: either by optimising the hull design, or by reducing the weight. Less weight means less displacement.”

Making waves

Although naval architecture has changed significantly thanks to CFD calculations, still every Heesen hull has to pass extensive tank tests to make sure the numbers add up. Watch the video to discover how it’s done.

Sjoerd van Herk

Senior naval architect Heesen Yachts

Balancing efficiency and stability

“Of course, Cosmos is an extreme example, but hull efficiency is at the heart of every Heesen yacht,” van Herk explains. "We always start with the owner’s wish list, which then leads to a first sketch of the General Arrangement. We know that a canoe-shaped yacht with a long hull and a narrow beam is good for efficiency. At the same time we want the yacht to be stable and spacious to accommodate all the client’s wishes. But there’s always a sweet spot, balancing efficiency and stability.”

To reach the required top speed, naval architects are hesitant to simply add installed power.

Highlights in hull efficiency

40 years of constant evolution in hull design have lead to some spectacular innovations at Heesen; these are the highlights.

Revolution in naval architecture

These impressive results are only possible thanks to a revolution in naval architecture, enabled by Computational Fluid Dynamics (CFD) testing.

"Naval architecture truly has evolved into a science,” says van Herk. “In the old days you would draw a hull based on experience, which you would then fine-tune by performing tank tests. Nowadays we still use tank tests, but only to verify the computer data that we are already very sure of.”

Over the years, Heesen has pioneered radical new hull designs together with longstanding partner Van Oossanen Naval Architects. In 2005 Van Oossanen were one of the first to employ CFD. Ever since they have been feeding their supercomputer with many different simulations, making CFD testing just as realistic and reliable as tank testing.

What does the future hold?

The FDHF has improved even further over the years, with the latest version implemented on Project Cosmos. But also in other departments efficiency is gained. More recently, Heesen has been optimising the propeller design with CFD, which helps to improve noise levels on board. Another development is the integrated exhaust design, which also reduces drag.

Battery power

Despite being the world’s largest and fastest all-aluminium yacht, Project Cosmos also boasts impressive efficiency-enhancing solutions. A battery pack of 567 kWh allows her to stay at anchor without any generator running for two hours. The same battery pack provides peak-shaving capability to prevent generators starting up when demand for hotel services is high.

Keep it light

Lightweight interiors are essential to reduce the weight of a yacht, and Heesen has turned furniture construction into an art form. Perforated or honeycomb fittings, floors and wall panels are used to save weight for the fixed furniture throughout the yacht interiors.

AluminiumHoney Comb Structure

MarbleTop Layer Finish